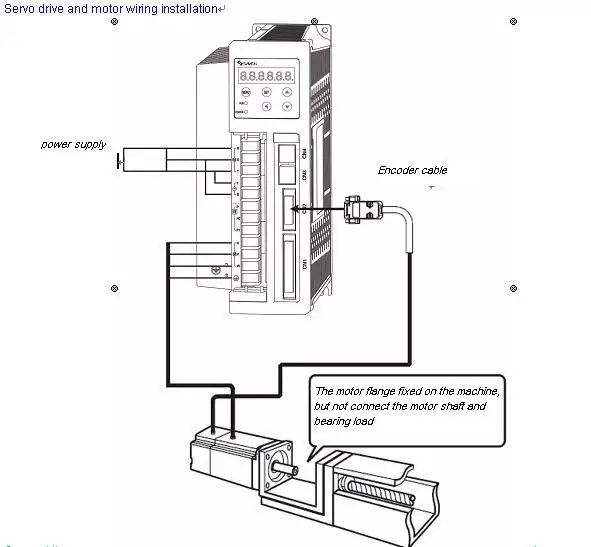

Ac Servo Motor Driver Schematic

Integrated circuits and reference designs for servo drive control module systems, complete with schematics, test data and design files. Control AC motor speed with. AC servo motor are required for a high. Three-phase Brushless AC motor driver. The driver circuit is required to drive. This is the simple basic design of servo motor controller with pulse generator. It uses the CMOS IC 7555 in the Astable mode to generate pulses to drive th.

Hello dear machinists! A long time ago I tried to build my own servo drive (and I almost did), based on ELM CHAN Servo drive schematics and code. I am now building an AC servo drive from scratch. I have my own program, and my own schematic. After a couple of weeks of hard working, reading, soldering and programming this is what I obtained: A cheap servo drive, based on ATMEGA644 (lower versions can also be used as compiled program hardly occupies 15% of MCU flash). The whole boar wont cost you more than 30$!!!

The features so far: Works with AC motors without using any Hall sensors. Step / Dir inputs UART connection for tuning and debuging I can tell you that I am really happy with the performance obtained so far. My own build servo (a cdrom motor and an optic encoder from an old mouse) works really fine. I was able to obtain about 1200 RPM with this 6 poles motor and 90 PPR encoder.

Little software / hardware description. MCU must have 6 pwm outputs and 3 external interrupts. 3 x IR2101 are used for driving the final stage mosfets. 1 x 74hc14 is used to buffer my encoder inputs.

16 Mhz clock on MCU (can be raised to 20 Mhz) PID process for controlling movement. I will make the schematic and source code available for anyone here.

Please feel free to modify them as you need (they are not under any kind of licensing) Here are some pictures and video of my very beta board and servo! Short description of software commands: 1. 'getconfig' - will display the config parameters stored in the EEPROM example output: CONFIG: ENCODER PPR = 90 MAX PPR ERROR = 45 MOTOR POLES = 6 PID Kp = 450 PID Ki = 350 PID Kd = 100 2.

'set ppr XXXX' - will set the PPR rate of the encoder. XXXX must be unsigned int 16 3. Cherokee Ah-100 Manual here.

'set error XXXX' - will set the max allowed error. If during movement the EncoderPosition - DesiredPosition is greater than this value servo stops and error led is powered. This is used only when STEP/DIR commands are applied. XXXX must be unsigned int 16 4.

'set poles XXXX' - will set the number of poles of the motor. (I am not sure about this terminology, what I did is: for eg. 6 poles means the motor makes a full turn in 6 sine periods) 5. 'set kp XXXX', 'set ki XXXX', 'set kd XXXX' - will set Kp, Ki and Kd constants of PID process calculation. 'start', 'stop' - starts or stops the PID process.

The Walking Dead Survival Instinct Pc Keygen Password. If stopped no power is applied to motor and PID calculation is stopped. 'enc' - will display the encoder position register (Int 32 signed). PID must be stopped to allow this 8. 'move XXX'X - starts a free movement of XXXX steps.

During this the max allowed error is set to max int 32 so no error will be raised during this kind of move. Give it a try.

Table of Contents • • • • • • • What are Servo Motors? A servo motor is a linear or rotary actuator that provides fast precision position control for closed-loop position control applications. Unlike large industrial motors, a servo motor is not used for continuous energy conversion. Servo motors have a high speed response due to low inertia and are designed with small diameter and long rotor length. Then how do servo motors work? Servo motors work on servo mechanism that uses position feedback to control the speed and final position of the motor.

Internally, a servo motor combines a motor, feedback circuit, controller and other electronic circuit. It uses encoder or speed sensor to provide speed feedback and position. This feedback signal is compared with input command position (desired position of the motor corresponding to a load), and produces the error signal (if there exist a difference between them).